Wire & rod processing

>> Variety of wire rope types

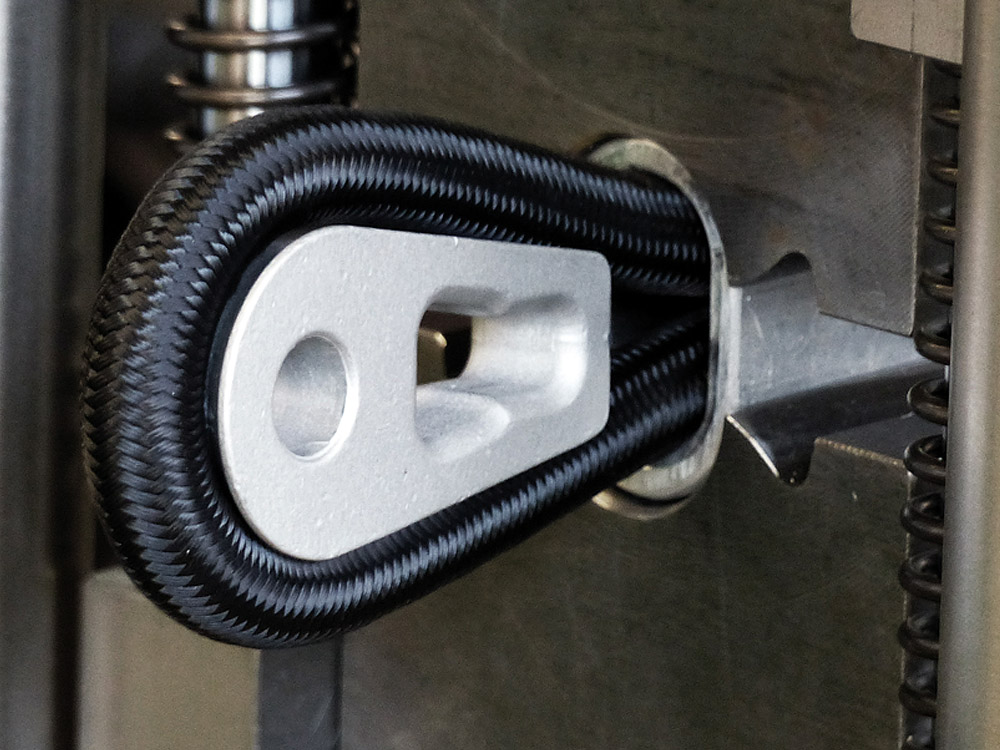

>> Flexible end connections

>> Single part & series production

Wire and rod processing - rolling, pressing, upsetting

BARTELS Wire Rope Processing offers customised solutions for all requirements in railway technology. We process all types of wire ropes - from flexible wire ropes and high-strength ropes to special full rod cross-sections. We assemble standard or special terminations at the ends according to customer requirements, whereby full rod cross-sections are fitted with an upsetting head.

We process wire ropes with diameters from 3 mm to 12 mm and manufacture both individual samples and series production. State-of-the-art production technologies such as terminal rolling guarantee precise and reliable connections. In addition, we subject our products to stringent tensile tests to ensure maximum safety and performance.

Put your trust in BARTELS Wire Rope Processing - your expert partner for innovative, customised and resilient rope assemblies. Our many years of experience and our technical expertise ensure customised solutions that meet the high demands of the railway industry.

Examples of railway wire ropes

Terminal rolling

BARTELS offers tested rolling and pressing processes for wire ropes in 1x19, 7x19, 6x36, Dyform and special wire ropes. Our highly flexible, customised ropes are processed using state-of-the-art technologies to guarantee optimum mechanical properties and a long service life. All standard terminations can be applied as end terminations - according to the requirements of the railway industry. In addition, we develop any special designs on customer request, which are tested and produced in series.

Our wire ropes are mainly manufactured from corrosion-resistant 316/A4 stainless steel. Alternatively, galvanised steel wires can also be used as wire material. With our many years of experience in wire rope processing, we ensure that every solution meets the highest quality and safety standards and can be perfectly integrated into demanding applications.

Rely on BARTELS for customised, high-performance wire rope assemblies that meet the specific requirements of the railway industry.

Rod compression

BARTELS offers specialised processes for the rod upsetting of high-strength solid wires, which have special requirements due to their low flexibility. For wires with a diameter of over 5 mm, a head is swaged onto the end of the wire. This positive connection in conjunction with the appropriate counterpart ensures a heavy-duty, secure contact that exceeds the breaking load of the wire rope. By using state-of-the-art technologies and strict quality controls, we ensure that every connection meets the high requirements of the railway industry. Rely on BARTELS' many years of expertise in wire rope processing and rod compression - for reliable, high-performance components in heavy-duty applications.

Pressing AT ropes / Pressing ropes

BARTELS offers specialised processes for pressing and processing anti-torsion ropes and other rope systems that can be pressed with end connections. This involves creating a friction-locked connection between textile materials and metallic end connections, which are used at the force-transmitting points. Textiles offer significant advantages in terms of weight, flexibility, breaking load and fatigue strength. By using the latest pressing processes and precise production technologies, we are able to make optimum use of these advantages and realise a highly resilient, secure connection. Put your trust in BARTELS, your expert for innovative connection technology that combines textile and metal components to create high-performance, durable solutions.

Wire rope assembly

BARTELS manufactures all types of wire ropes - from flexible to rigid wire ropes, rod wire ropes and textile ropes, each of which offers its own specific technical advantages. As standard, we process wire ropes on a variety of rollers and presses with a diameter of up to 17 mm and achieve production lengths of up to 35 metres. If longer lengths are required, we can also produce these on request.

We keep standard wire ropes and terminals in stock so that we can manufacture customised wire ropes at short notice. Special terminations are designed in a short space of time and manufactured in our in-house production facility - this means that special, customised wire ropes can also be produced quickly.

A tensile test rig is available to test and document the strength of the wire ropes and their end terminations. All production processes are carried out within the framework of our quality management system in accordance with DIN ISO 9001:2015.

Ask us - we will find the right wire rope solution for your project.