Flexible production

everything from a single source

>> large machine park

>> flexible production

>> high vertical range of manufacture

Flexible production - everything from a single source

BARTELS Railway Components offers flexible manufacturing solutions from a single source. Our extensive range of machinery enables us to process metal from sheet metal to tubular components, with all manufacturing processes carried out in-house - from traditional processes such as sheet metal shearing and conventional machining to state-of-the-art CNC technology.

We develop customised solutions for deep-drawn parts, bent parts and welding fixtures in our in-house toolmaking department. This comprehensive vertical range of manufacture makes BARTELS particularly flexible - a decisive advantage in an industry in which highly specialised production companies often only cover individual segments.

Our experienced technicians, master craftsmen and engineers contribute decades of expertise to the efficient realisation of complex projects - whether in prototype development, sample production or series production. With maximum precision, on-time delivery and customised solutions, we ensure the success of your railway applications.

Put your trust in BARTELS Railway Components - your competent partner for flexible manufacturing solutions that combine innovation and comprehensive expertise.

Examples of railway components / assemblies

Flexible CNC and conventional production

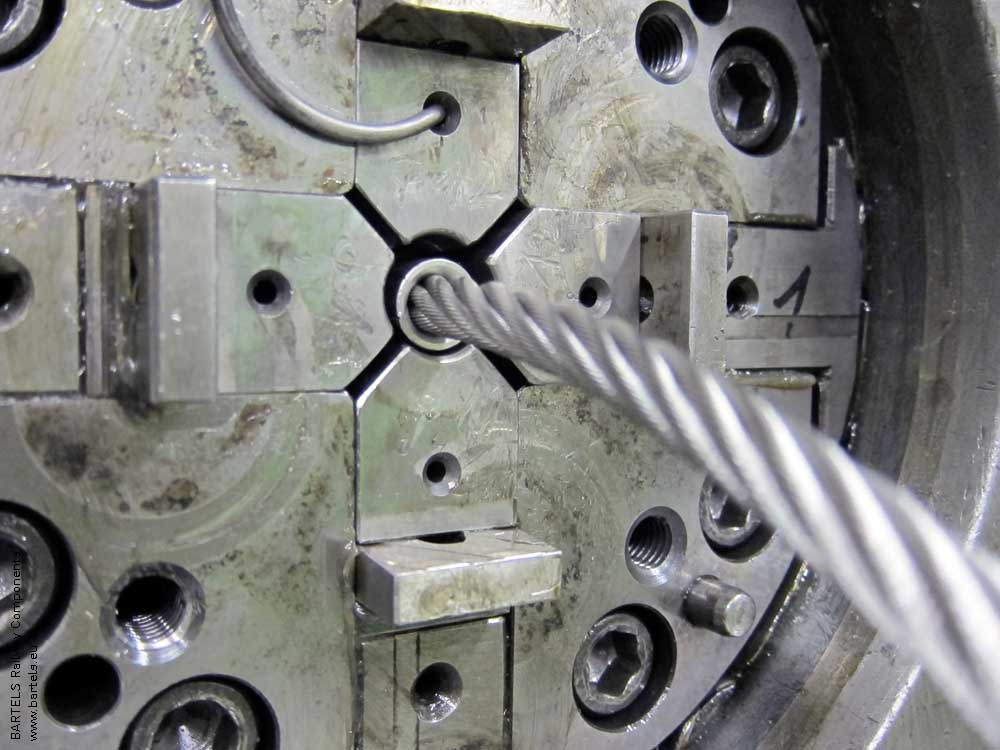

Bartels manufactures flexible and highly flexible wire ropes with compact end connections, so-called terminals - tested for breaking load and made from corrosion-resistant stainless steel materials.

The picture shows a threaded terminal with inserted wire and full thread length. After pressing, the thread is applied using a rolling process to ensure a particularly high load-bearing capacity of the threads. Highly specialised machines are used for secure pressing.

Whether individual parts, series production or prototyping - everything is possible. Rely on proven standards with experience or work with us to develop a customised solution for your application.

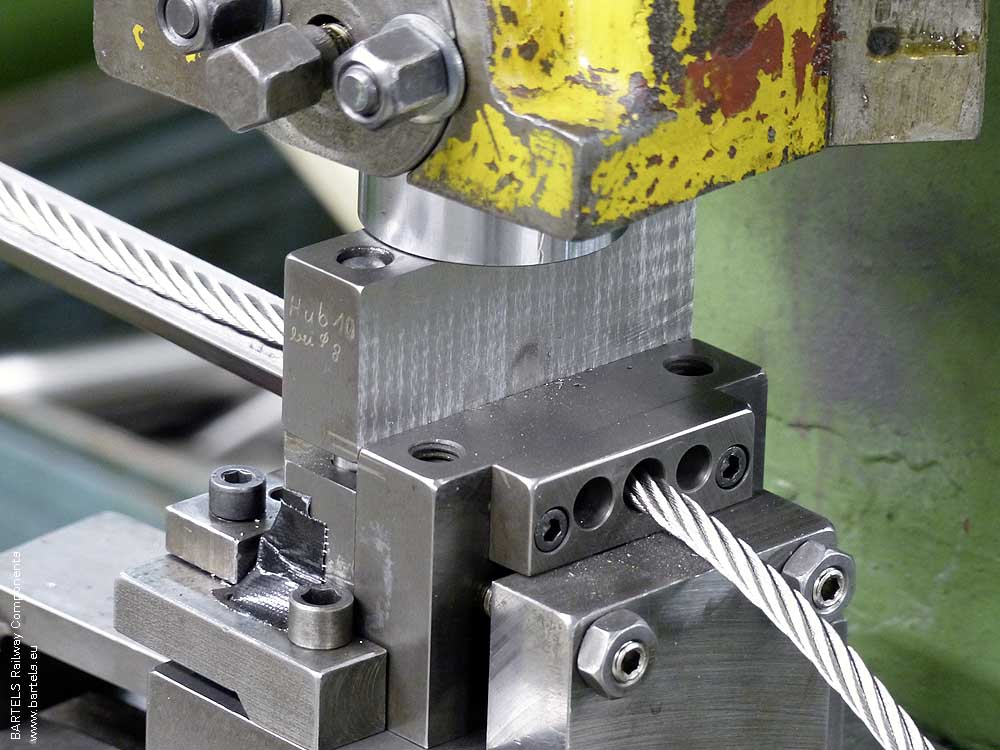

Forging terminal

BARTELS Wire Rope Processing is your expert when it comes to applying terminals using the forging process. The terminals are applied directly to the wire using the forging process - a method that creates a particularly homogeneous and strong connection between the wire and terminal. This precise process minimises potential weak points and ensures reliable power transmission in railway applications. State-of-the-art production technologies and strict quality controls guarantee exact tolerances and high corrosion resistance. Whether standard terminals or individually designed special constructions - BARTELS offers customised solutions that meet the demanding requirements of the railway industry. You can rely on our many years of expertise in wire rope processing to realise durable and high-performance terminations for your wire ropes.

Edges

BARTELS offers precise sheet metal edging for customised production solutions. Using state-of-the-art CNC technology and extensive machinery, we process sheet metal according to customer-specific requirements. Whether standard profiles or complex customised products - our experienced specialists guarantee maximum accuracy of fit and first-class surface quality. Thanks to integrated process control and continuous quality control, we achieve minimum tolerances and consistent results that meet the high requirements of railway technology and other industries. Put your trust in BARTELS as your reliable partner for sheet metal processing - everything from a single source, on time and cost-effectively.

Tube bending

BARTELS offers precise tube bending processes for customised production solutions. Using state-of-the-art CNC-controlled technology, we bend any tubes up to a diameter of 40 mm - regardless of whether they are standard profiles or complex special designs. We guarantee exact bending radii, minimal shape deviations and outstanding surface quality. Our wide range of machinery and experienced team enable us to realise your projects on time, while at the same time ensuring cost-effective production processes. Thanks to integrated process control and precise adjustment, we achieve customised solutions that meet the high demands of railway technology and other industries. Put your trust in BARTELS tube bending for reliable, durable and customised production solutions - all from a single source.

CNC 5-axis machining

BARTELS relies on state-of-the-art CNC 5-axis machining to produce even the most complex components with maximum precision and efficiency. By using advanced 5-axis technology, we can easily realise complex geometries and tight tolerances - ideal for demanding railway technology applications. Whether individual parts or series production, our state-of-the-art machines and experienced team guarantee first-class results in the shortest possible time. Thanks to seamlessly integrated process steps from design to surface finishing, we achieve the highest quality standards that meet the requirements of the railway industry. Put your trust in BARTELS as your reliable partner for complex 5-axis machining - everything from a single source, on time and cost-effectively.

Wire rope processing

BARTELS Wire Rope Processing stands for maximum precision and reliability in the production of customised wire rope solutions. Flexible and high-strength wire ropes of various types - including 1x19, 7x19, Dyform and special rod wire ropes - are precisely processed and assembled using state-of-the-art manufacturing processes. Our end terminations, whether standard or customised, are applied directly to the wire using innovative rolling and forging processes, ensuring a homogeneous and durable connection. BARTELS uses a wide variety of materials, such as stainless steel, aluminium, steel, copper and titanium, to meet the demanding requirements of railway technology. Thanks to flexible manufacturing processes, customisation and strict quality controls, we manufacture both prototypes and series production - all from a single source. Rely on BARTELS as your competent partner for precise and high-performance wire rope processing.

Sheet metal bending & deep drawing

BARTELS offers comprehensive toolmaking solutions for deep-drawing tools and presses that can be used to produce components of almost any shape. In our in-house toolmaking department, we transform small quantities of material into stable, three-dimensional structures. Our highly qualified specialists develop and manufacture customised deep-drawing tools that are precisely tailored to your requirements. Using state-of-the-art pressing systems, we achieve maximum precision and efficiency in the production of deep-drawn components, whether in prototype construction or series production. At BARTELS, you receive a complete service from a single source - from design and toolmaking to the production of high-quality deep-drawn components. You can rely on our many years of experience and innovative strength to transform your components into stable 3D moulds and thus realise cost-efficient, customised solutions.