Production examples

for railway applications

>> Overrun horns, wind deflectors, ...

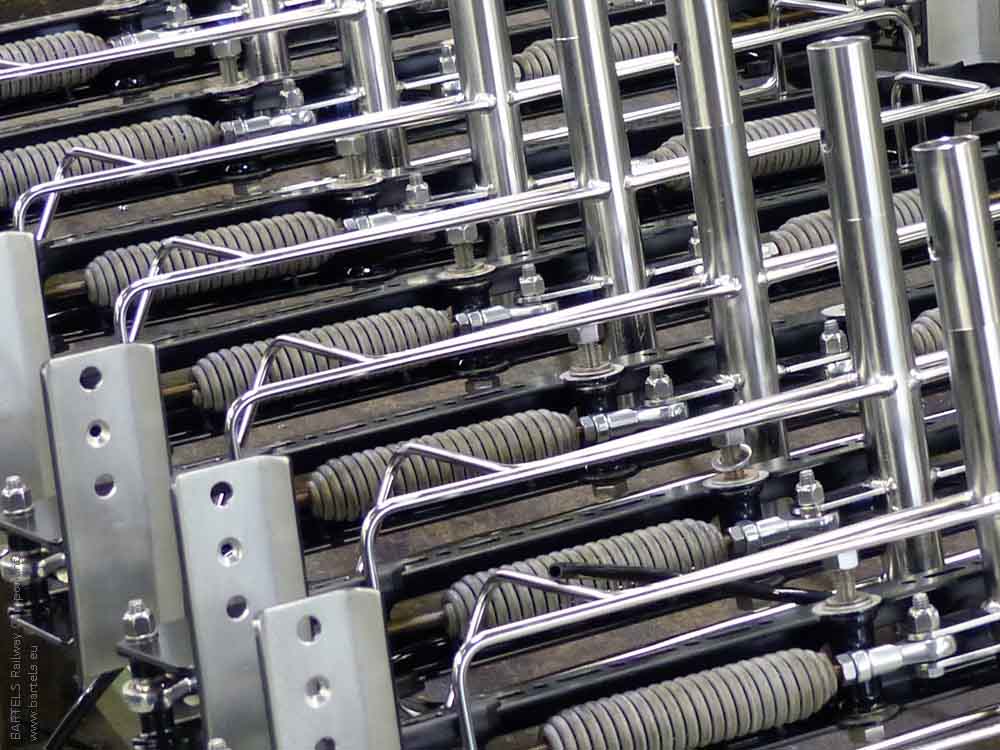

>> Rocker assemblies

>> Current collectors

Production examples for railway applications

BARTELS Railway Components offers you a comprehensive portfolio of production examples for railway applications. Our innovative solutions and precision-manufactured components fulfil the stringent requirements of the modern railway industry. We produce high-quality wind deflectors to optimise aerodynamic forces and robust overrun horns to ensure that pantographs enter the overhead contact line safely.

Our customised rocker assemblies guarantee the guidance of contact strips and are essential for high-speed transport. Our range is complemented by specially developed tramway and mainline pantographs, which impress with their durability and maximum performance. In addition, we also manufacture guide rods and individually configurable wire ropes that offer a wide range of possible applications. Our powerful hoist drives provide reliable drive support in critical applications.

We also offer comprehensive repair and retrofit services to restore and modernise old components. Rolling cures are also carried out to the highest quality standards - flexibly and on schedule.

Put your trust in BARTELS Railway Components - your competent partner for innovative, precise and reliable railway technology solutions.

Examples of railway components / assemblies

Components / assemblies for railway applications

BARTELS manufactures high-quality components and assemblies for railway applications, which are mainly used in the field of pantographs. Our production is based either on customer-specific drawings or on sample components if drawings are no longer available. The comprehensive product portfolio includes series parts such as wire ropes, rocker assemblies, overrun horns, tension wires, rocker guide rods, link rods, frames, pressure technology and special welded parts made of titanium, aluminium, steel and stainless steel.

With a high level of vertical integration in-house and over 70 machines, we offer all process steps from a single source: from precise cutting to state-of-the-art CNC production, welding, assembly and testing through to professional surface treatment. The latter includes functional coatings such as hard coatings and corrosion protection coatings by painting or powder coating. Our processes meet the highest safety and quality standards thanks to railway welding approval and quality management in accordance with DIN ISO 9001:2015.

With decades of experience in the development and production of pantographs for trams and mainline railways and a Europe-wide network in the railway technology industry, BARTELS is a reliable supplier of ready-to-install parts and assemblies. Rely on us for precise, customised solutions and fast, reliable deliveries. Contact us for customised advice and manufacturing solutions that are precisely tailored to your requirements.

Wire ropes for railway applications

BARTELS manufactures wire ropes for railway applications that meet the highest requirements in terms of safety, corrosion resistance, bending strength and precise tolerances. Our wire ropes are characterised by special bending properties and are designed with end terminations in unusual dimensions - precisely adapted to the requirements of pantographs and other critical railway technology components.

With short delivery times, we realise orders from a few units to several thousand units reliably and flexibly. Our production processes comply with the DIN ISO 9001 quality standard, and our in-depth expertise in the field of pantographs ensures compliance with all safety-related specifications.

As a reliable supplier of special and standard wire ropes, BARTELS offers customised solutions that are individually tailored to your project requirements. Put your trust in our expertise and precision to master your railway engineering challenges in the best possible way.

Rollkur components / assemblies

In the context of railway technology, the term roll cure at BARTELS Railway Components refers to the reworking of a series during operation by removing small batches for existing, older systems. These specially produced components - often as spare parts for moving elements in pantographs or other assemblies - are manufactured precisely according to original drawings or customer-specific requirements. The aim of the rolling cure is to ensure functionality and safety when the original components are no longer available. By using modern manufacturing technologies and high-quality materials, BARTELS ensures that these spare parts fit precisely and perform well to ensure the operational safety and longevity of critical railway technology components.

Titanium welded components according to DIN EN 15085 (customised)

BARTELS specialises in the processing of titanium materials in sheet, tube and bar form. We manufacture customised components and assemblies that are joined precisely and durably using the latest welding techniques in accordance with DIN EN 15085. Our railway technical approval for titanium guarantees that all weld seams meet the strict requirements of the railway industry.

Titanium is characterised by its unique combination of high strength and low weight - a vibration-resistant, corrosion-resistant material that is ideal for demanding applications. With our experience in titanium welding, we can offer you customised solutions that are precisely tailored to your project requirements. We provide you with comprehensive advice on the advantages and possible applications of titanium and create a customised offer for your titanium components and assemblies.

Thanks to our close network with leading titanium suppliers, we ensure that the right titanium material is always available in the right material class at attractive conditions. Rely on BARTELS as your expert in the processing of titanium - for innovative, durable and high-strength welded components that meet the highest quality standards.

Wind deflectors (customised)

BARTELS manufactures individual wind deflectors for the aerodynamic optimisation of the contact wire contact force on pantographs. Our specially developed air deflectors regulate the air flow so that the contact strips are pressed against the contact wire with as constant a force as possible across the entire speed spectrum. Precisely coordinated contact pressure is crucial: too much pressure leads to excessive wear on the carbon and contact wire, while too little pressure can cause dangerous arcing and splitting - conditions that lead to considerable damage to the contact strips and contact wire.

Our customised solutions ensure consistent, safe contact, increase the service life of components and minimise the risk of expensive repairs. Put your trust in BARTELS as your expert for innovative and reliable railway technology components that meet the highest safety and quality standards.

Stainless steel handlebars

BARTELS manufactures handlebars for pantographs of the highest quality - all from a single source. In large series, our stainless steel handlebars are moulded in one piece and without weld seams, thus avoiding weak points. Integrated threads and spanner flats enable the direct attachment of add-on parts such as ball heads. This results in low unit costs, reduced weight and superior stability.

Our handlebars can be customised in length, diameter and connection components to precisely meet the requirements of your application. In addition to stainless steel, we also use high-quality materials such as steel or CFRP, depending on the specific technical requirements.

With a high level of vertical integration and a comprehensive in-house process - from material processing and moulding to final assembly - BARTELS guarantees precise and reliable components as well as short delivery times. Put your trust in our experience and customised solutions for secure and durable fastening in railway applications.

Spare parts according to drawing or sample

BARTELS Railway Components manufactures spare parts precisely according to drawings or samples - and exactly to your specifications. Whether it's spare parts for pantographs or other railway components, we provide you with customised solutions of the highest quality. If spare parts are initially required as samples, we create detailed drawings of the sample parts, which serve as the basis for series production - so that the next time an exact drawing is available.

Our comprehensive manufacturing process covers all steps: from the initial drawing, material procurement, laser cutting, bending, drilling, milling, turning and CNC machining to welding in accordance with DIN EN 15085, surface treatment and finally the assembly of ready-to-install components. At BARTELS Railway Components, you get everything from a single source - efficiently, on time and to railway technology quality standards.

You can rely on our many years of experience in the manufacture of spare parts for railway applications. Contact us for individual advice and customised solutions that precisely meet your requirements.

Overrunning horns on aluminium, titanium, stainless steel and GRP

BARTELS manufactures contact horns in series from aluminium, titanium, stainless steel and GRP to optimally guide the contact wire in pantograph systems. These contact horns prevent the contact wire from penetrating below the rocker if the contact wire is outside the specified tolerances. They must be particularly lightweight, yet robust, so that they can assume their emergency guidance properties within fractions of a second in the event of contact.

We often use titanium tubes as they offer an ideal ratio of lightness and stability. In addition, the upper side can be provided with a hard coating to extend the service life. Alternatively, we manufacture overrun horns made of GRP, which are also lightweight and robust. There is also the option of pneumatic monitoring for GRP overrun horns.

In combination with a rapid lowering device on the pantograph, the pantograph can be quickly lowered onto the train roof in the event of a fault - for example if the contact wire is outside the tolerance range or the contact strip or the top layer of the contact horn is damaged. This prevents major damage to the pantograph, train and especially the contact wire system.

Contact us for customised advice - BARTELS is your certified expert in the development and production of overrun horns. You can rely on our customised, high-quality assemblies that meet the high demands of railway technology.

Rocker assemblies for tram and mainline railway

BARTELS manufactures components and complete rocker assemblies for pantographs that ensure optimum contact behaviour of the contact strips on the contact wire. This contact pressure behaviour is crucial for the longevity of both components - while wear should primarily occur on the replaceable contact strips, the contact wire system, which is complex and cost-intensive to replace, is spared as much as possible.

Our rocker assemblies are characterised by their high vibration resistance, low weight and responsive properties, enabling them to safely and efficiently control the sensitive interface between train and contact wire, which ensures the entire energy transmission for train operation.

Thanks to state-of-the-art manufacturing technologies and strict quality controls, BARTELS offers customised solutions that meet the diverse requirements of railway technology. Rely on our expertise to maximise the service life of contact strips and contact wire and ensure a safe, reliable railway operating system.

Tram pantograph DO2106 (DOZLER)

DO2106 half-scissor pantograph - Proven quality from BARTELS Railway Components

BARTELS has been manufacturing railway pantographs for trams and mainline railways for over 50 years. The DO2106 half-scissor pantograph impresses with its robust and extremely proven design. The technical data includes

- Contact wire voltage: 800 - 1,500 V/DC

- Working stroke: 2300 mm

- Sliding strip length: 1050 mm

- Sanding strip width: 60 mm

- Total width: 1700 mm

- Nominal contact pressure: 70 N

These precise parameters ensure a constant contact pressure of the contact strips on the contact wire, which achieves optimum contact and minimises wear. The DO2106 is not only cost-effective to produce, but also easy to maintain - many maintenance tasks can be carried out by the operators themselves, resulting in considerable savings in operating costs.

In addition to the DO2106 series product, BARTELS also develops customised current collectors and spare parts for individual applications in the railway industry. Our extended portfolio also includes measuring current collectors such as the FM 2k series, which record contact wire parameters.

With decades of experience in the production of individual parts and assemblies for mainline railways and a Europe-wide network, BARTELS is your reliable partner - from goods trains to ICEs. We are always available to provide you with detailed information and customised advice.

Measuring current collector FM 2k (DOZLER)

The FM 2k (DOZLER) measuring current collector is a contact wire measuring system that has been specially developed for railway applications. This system makes it possible to precisely measure the vertical contact wire position both at rest and during the lifting process with variably adjustable contact forces and to record it over the course of the track. This allows deviations in the vertical stiffness and the regular position of the contact wire to be recognised at an early stage in order to avoid increased wear and a risk to operational safety.

The most important parameters of the FM 2k system are

- Contact pressure: Adjustable from 8 N to 250 N

- Working stroke: 2500 mm

- Contact pressure curve: Constant over the entire stroke, electronically controlled

- Mass: 110 kg

This precise measurement data is essential to ensure the optimum contact pressure of the sanding strips - a critical factor, as forces that are too high or too low can lead to excessive wear or dangerous arcing. The FM 2k measuring system offers both standard and customised versions with adapted interfaces and individual functions. As an option, the horizontal contact wire position can also be recorded to enable a comprehensive analysis.

Benefit from our many years of expertise and customised solutions in railway technology. We are always available to provide you with detailed information and customised advice. Contact BARTELS Railway Components - your reliable partner for innovative and safe measurement technology in the railway sector.